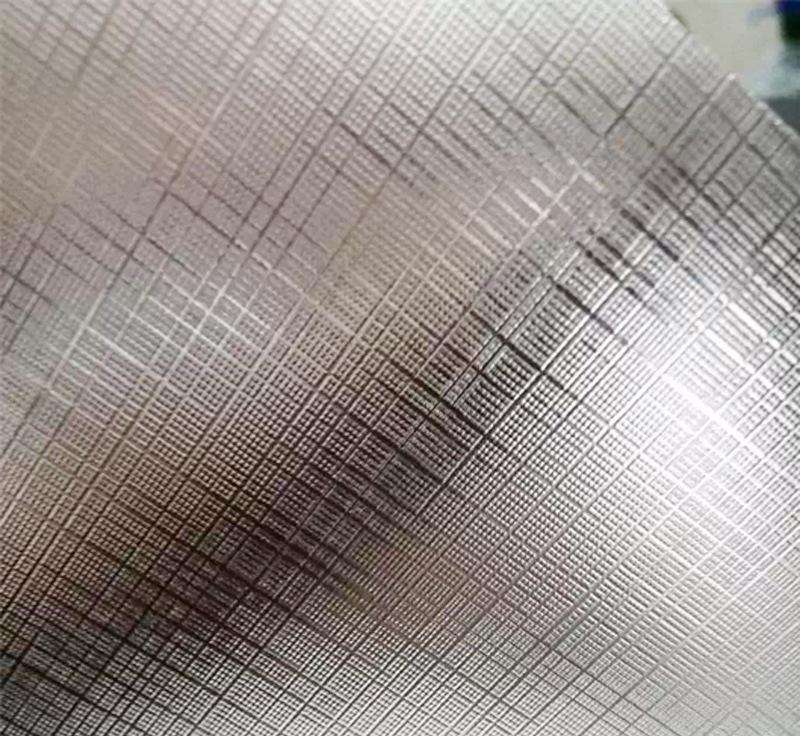

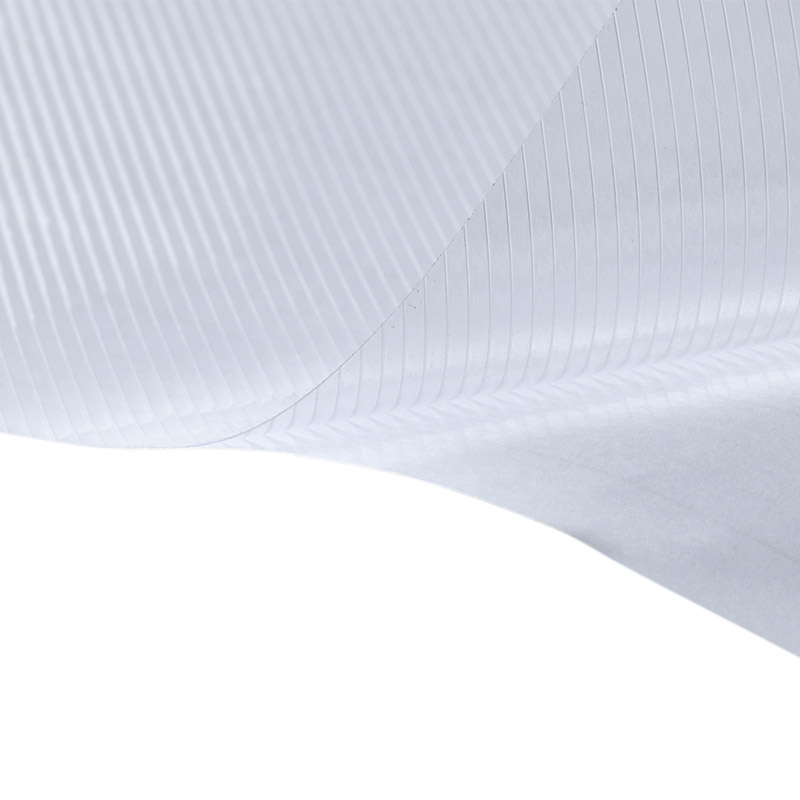

| Base Material | Single matte PP Synthetic Paper |

| Thickness | 215 microns |

| Finish | Available in white with matte surfaces |

| Available Lengths | 50m |

| Available Widths (in meters) | 0.914 |

| Print Compatibility | Eco-solvent |

Parameter:

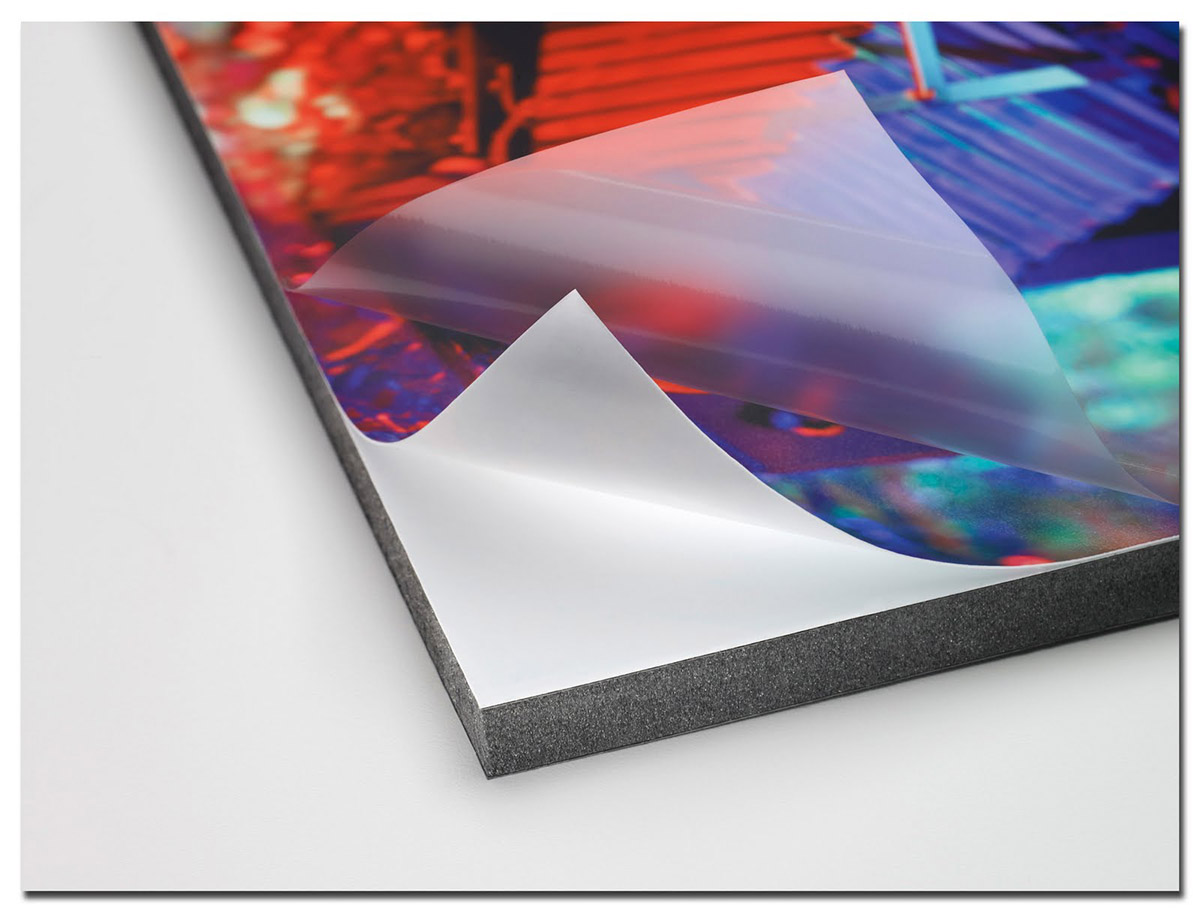

Matte Eco-solvent PP Synthetic Paper

PP Paper, also known as Polypropylene Paper or Synthetic Paper, is a unique and versatile material that has gained popularity in the printing and packaging industries. It is made from polypropylene, a thermoplastic polymer known for its exceptional properties.

This product is coated with eco-solvent coating.

Applications

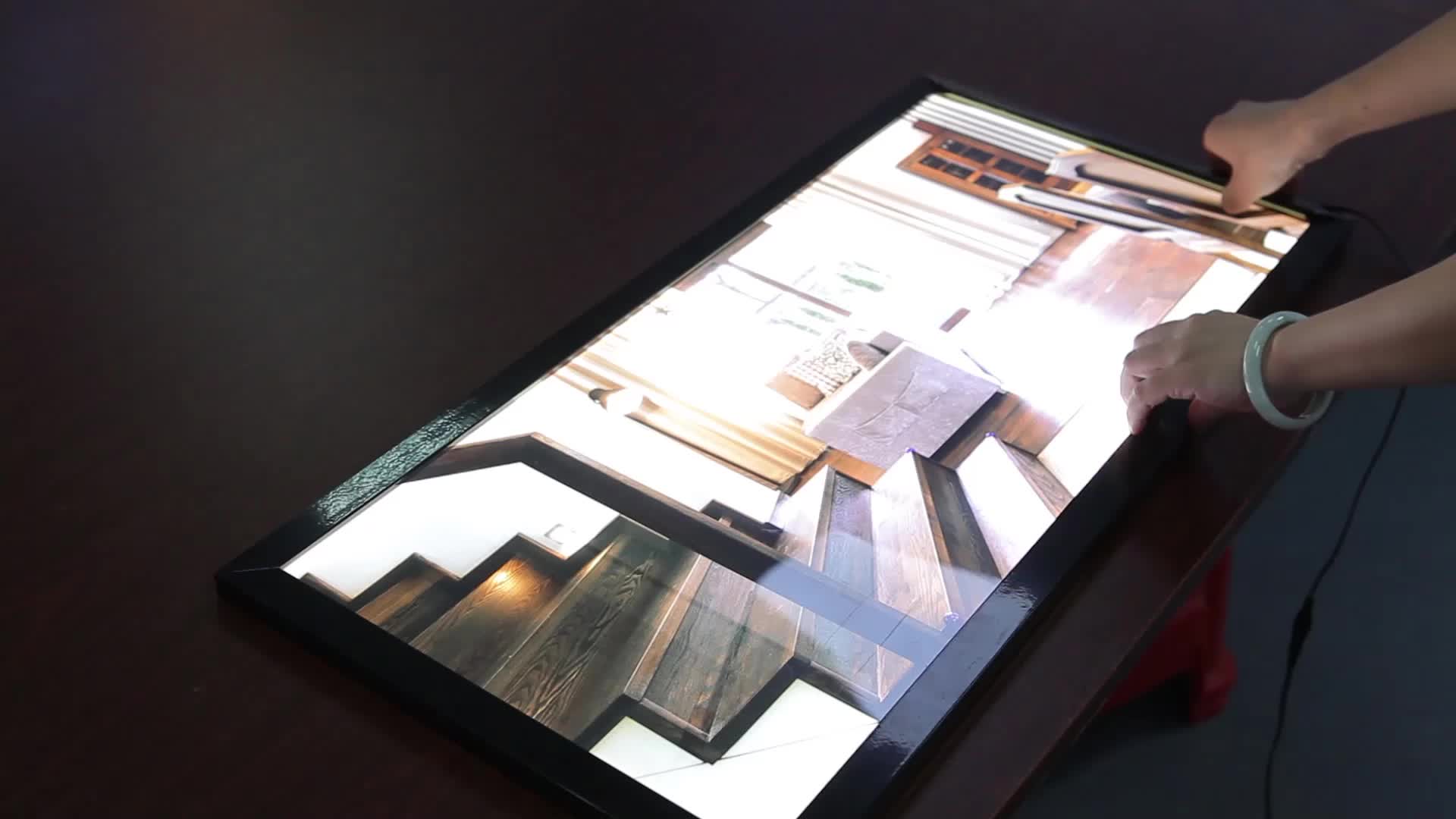

- Short-term general signage for flat and slightly surfaces applications

- Indoor and outdoor advertising applications

- Roll up banner

- Posters, Board display

- Image display

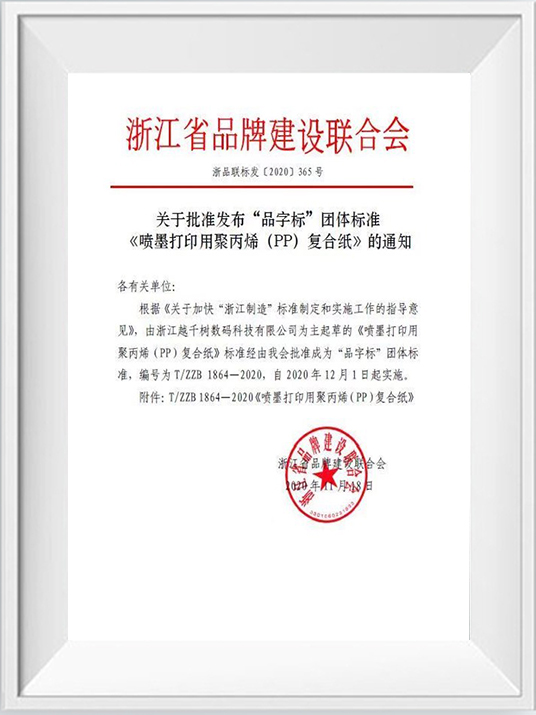

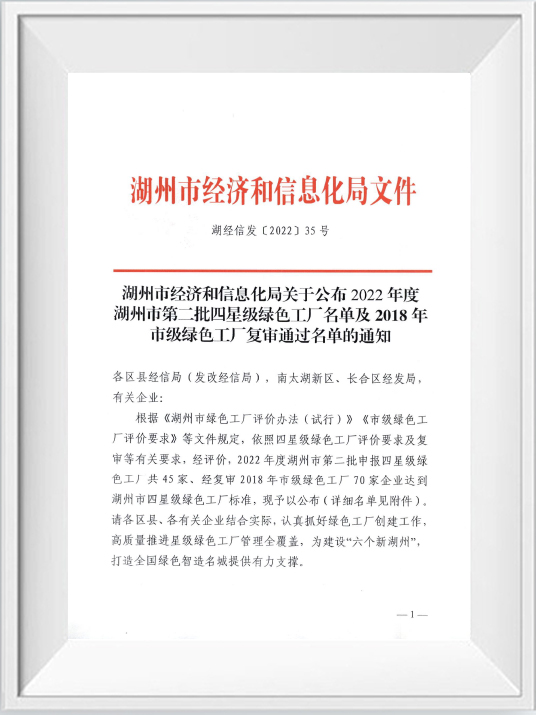

Zhejiang Yueqianshu Digital Technology Co., Ltd is well known China Matte Eco-solvent PP Synthetic Paper manufacturers and Matte Eco-solvent PP Synthetic Paper factory, we supply wholesale Matte Eco-solvent PP Synthetic Paper for sale. The company's main product applications include indoor and outdoor advertising design, architectural design, indoor and outdoor decoration applications, photo studio printing, office and personalized digital printout, clothing printing and other fields.

At the same time, the company is also constantly expanding in the fields of new materials such as automotive functional films and electronic films to achieve diversification and multi-track development of related industries.

Experience

Innovation for a sustainable future.

-

0

Production Line

-

0

Patent Certificate

-

0Hundred

MillionFactory Area

-

0+

Partner Dealer

-

Aug 25 -2025When we examine the surface of a piece of furniture or run our fingers over the ...

-

Aug 18 -2025In modern life, electronic devices have become indispensable companions. Whether...

-

Aug 11 -2025Have you ever marveled at the vivid colors, clarity, and three-dimensionality of...

-

Aug 04 -2025When children play on the floor at home, or customers rush through commercial sp...

-

Jul 24 -2025In the field of modern printed product protection, cold lamination film is resha...